Navitas project management, systems & processes, checks & balances, is what makes Navitas achieve desired performance standards. You will have a dedicated Project Manager to put together an effective project timing plan, he would communicate and exchange information with each department leading to effective solutions. Your Project Manager would organize meetings as and when required and submit weekly progress reports. All Navitas Project Managers are bilingual and technically strong so no information is lost in communication.

RFQ | Product type | Material type | Lifetime | Production volume | Cavity | Production place | Cycle time

Concept idea, feasibility study, cost targets, quotation

Project start, mould flow analysis, tool design, 2D/3D drawings

Tool building, milling/wire-cut, CNC/EDM/Polish, assembly

Tool trial & improve, full dimension check, ISIR report

Production (moulding/stamping)

Concept idea, feasibility study, cost targets, quotation

Project start, mould flow analysis, tool design, 2D/3D drawings

Tool building, milling/wire-cut, CNC/EDM/Polish, assembly

Tool trial & improve, full dimension check, ISIR report

Production (moulding/stamping)

Each project begins with a thorough understanding of customer standards and specifications. With years of experience and practical knowledge, our engineers offer all necessary assistance and information required to create your product and to follow its development through the production lines. Prior to tool design, our engineering team will review your product design and issue feasibility study reports, offering proposals, if any, for improvement of manufacturability, cycle time and part quality.

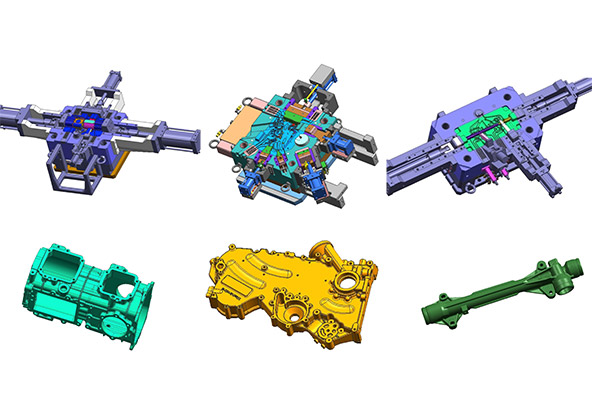

At Navitas, all parts and tools are optimized through simulation/mold-flow analysis for cooling, injection system, warpage, deflection, optimal molding conditions and various other parameters. We follow NADCA, Japnese and German stanadards for die development. Our team work on Unigraphics, Pro/E, AutoCAD, Solid Works, Pro-Mill, Flow 3D and Any-Casting for simulation.

Navitas toolrooms are well equipped with modern machines and equipment to achieve the required precision and standards.

Navitas’ tools are fully tested to make them production-ready prior to shipment to customers. Our engineers record testing parameters and provide you with trial reports along with full dimension reports. Upon customer request, we would carry out a trial production run to verify the stability of tool & part dimensions. We provide proto and low volume production through inhouse facility.

Serial/ Mass Production: Navitas has partnered with an advanced production house to offer serial/ mass production of large Giga/ Mega castings, machined and ready-to-assemble parts.

IATF16949 certified facility

Navitas follows “ZERO DEFECT POLICY” on any product shipped by the company. We have the necessary systems and controls in place to meet the highest quality standards. We maintain our product and service management systems to conform to industry standards and continually improve upon them. Navitas gets audited regularly by its customers and third-party auditors for process and operational controls.