Home » Sheet metal parts

Sheet metal parts

Housing And Enclosure

Energy Storage Battery Cabinet

Parts Production

Navitas toolrooms are fully tested to make them production-ready prior to shipment to customers. Our engineers record testing parameters and provide you with trial reports along with full dimension reports. Upon customer request, we would carry out a trial production run to verify the stability of tool & part dimensions. We provide proto and low volume production through inhouse facility.

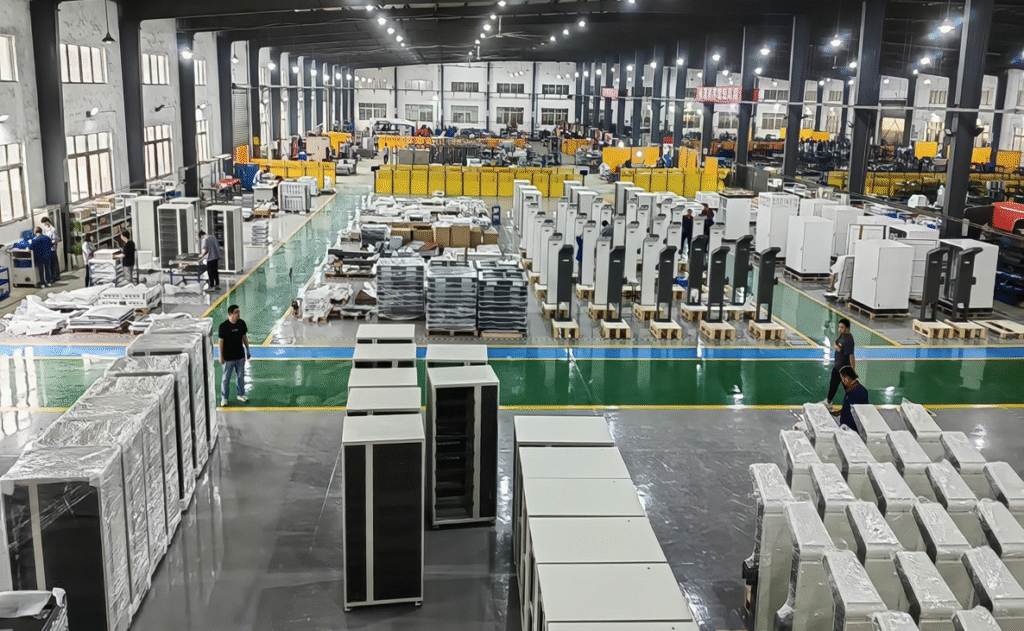

Serial/ Mass Production: We have production facility inhouse to offer serial/ mass production of large Sheet metal parts, machined, powder coated and ready-to-assemble parts/ assembled parts

Laser Cutting machine – 15 units

CNC Bending machine – 250T

Laser welding robo arm – 4 units

Coating / surface treatment facility

Others – Coding machine/cooling tank

IATF16949 certified facility

MACHINING

Navitas toolrooms are well equipped with modern machines and equipment to achieve the required precision and standards.

MANUFACTURING FACILITY

SHEET METAL TOOLROOM

Established: 1999

Certification: IATF16949 2016 & ISO9001:2015

Factory area: 32,500m²

Employees: around 250

Capacity: 250 Die casting dies/year (around 35% overseas)

Shift: 2-shift-operation (6 days per week)

Location: Ningbo, China

Die range in weight: 500T~ 6000T

Focused on Automotive, Precision dies and parts